With the rise in demand for electric and hybrid vehicles, protecting battery systems from harsh environments has never been more critical. The secret to enhancing battery performance, safety and reliability lies in implementing the most effective electro-chemical protection materials, particularly given the increasing trend towards high-capacity, fast charging battery packs. Electrolube’s extensive portfolio of resins, coatings and thermal management solutions supports the entire protection of EV batteries.

An EV customer in India recently approached Electrolube to help provide a solution for an issue with an existing coating they had used from a different supplier for their Battery Management System (BMS). The BMS continuously monitors parameters such as temperature, voltage and current in and out of the battery pack to ensure it is operating in safe conditions at all times. BMS is a critical system that’s responsible for the thermal management of the battery and not only adjusts cooling, but importantly, can trigger other safety mechanisms to stop operations and minimise risk. For instance, if overheating of the battery pack is detected by the BMS, the vehicle’s power output is automatically limited and the vehicle is put into fail-safe mode.

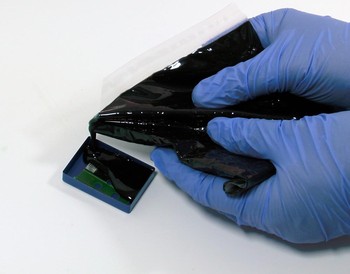

The EV battery customer required a robust, high performance coating that was scratch resistant, solvent-free and provided the highest level of protection against harsh environmnets. The next generation coating, UVCL, part of a wider range of UV cure coatings at Electrolube, was selected to protect the BMS with excellent results. The customer didn’t have a UV Curing facility in-house, subsequently Electrolube’s customer service team in India sourced a reputable supplier to assist them. After few iterations Proto sample Unit is prepared and unit put into field test.

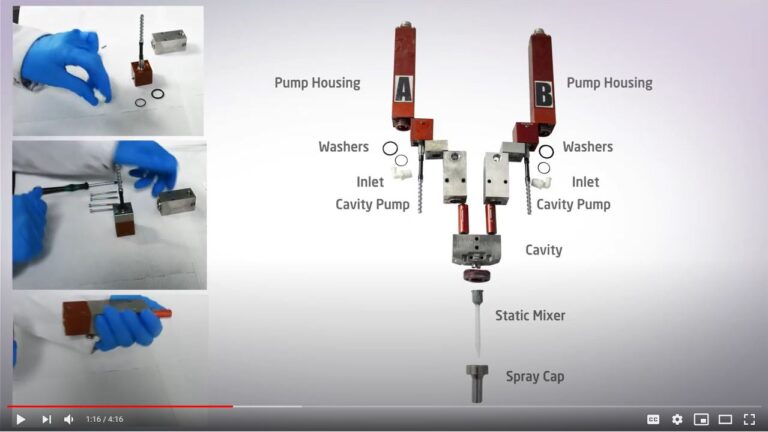

The low viscosity, single component UVCL provides the highest level of protection for electronic circuitry at high production throughputs. The coating also cures within seconds upon exposure to the correct dose of UV light and has a highly effective, moisture initiated secondary cure mechanism to ensure curing in shadowed areas. UVCL eliminates the use of solvents, being both VOC-free and non-flammable, and is applied via selective spray equipment. It has been widely tested with excellent results and demonstrates ease and speed of application in an automated process, achieving high-speed surface cure.

The UVCL coating allows the application of relatively thin films and requires no dilution, so it is ready to use instantly. It also provides excellent storage stability and a long shelf life. With the highest level of flexibility, the coating provides the ultimate protection in harsh environments, including high humidity, thermal shock, moisture, corrosive and chemical atmospheres at minimal cost. The coating also fluoresces under UV light for ease of inspection and offers excellent electrical properties with a wide operating temperature range of -65°C to +135°C.

Ron Jakeman, Managing Director of Electrolube, comments, “We are very pleased to have provided such a successful solution for this EV application, especially given the critical nature of BMS. Electrolube is experiencing increasing demand from EV battery designers and manufacturers, and we have been providing effective solutions that have have been tested and proven to address heat, performance and protection issues. We have always relished challenges, it’s what drives us to innovate constantly, and the EV battery industry is increasingly reaching out to us for solutions that safeguard every conceivable aspect of an EV battery to ensure they have every box ticked when it comes to safety, reliability and performance.”

With a presence in 60 countries, Electrolube is an established manufacturer of specialist chemical products supplying the world’s leading manufacturers of electronics, automotive, industrial and domestic devices. All product ranges are manufactured at the company’s BS EN ISO 9001, ISO 140001, “IATF 16949:2016, OHASA 18001 and AS/EN 9100 Series accredited factories in the UK, China and India.