In this month’s blog for Electrolube, I wanted to provide a little information on the subject of resins (yes, two puns in as many lines, completely intentional!). Essentially questioning the core rationale for their use in encapsulation and potting compounds; their fundamental chemistries and how each resin type differs one from the other – indeed, how their individual properties can be exploited to maximise performance under a wide range of environmental conditions.

So let’s start by going back to basics, why, where and how do we pot electronics?

1) Moisture:

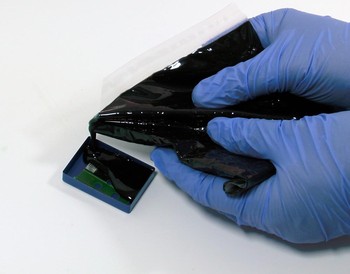

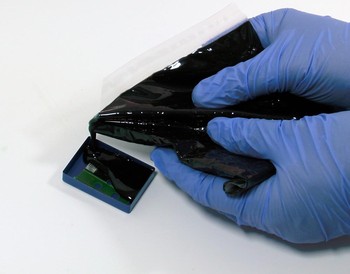

Now, let’s start with moisture; that is the arch enemy of electrical and electronic devices that, quite apart from causing short-circuits, can also lead to premature deterioration of components due to corrosion. There is a resolution for this, which is why resins are so important. Polyurethane resins – usually supplied as two-part products, which, when mixed achieve the desired cure and provide the all-important moisture resistance, as well as excellent electrical insulation, flexibility and good adhesion to most substrates. Furthermore some polyurethane potting compounds provide exceptional resistance to sea water, as well as temperature extremes, making them an ideal choice for marine applications such as sensor encapsulation. A good outdoor example of a polyurethane resin encapsulated component that requires maximum protection against water ingress is an LED lighting unit; these resins are also optically clear and UV stable, making them ideal for the task.

There are one-part moisture curing polyurethane resins available, but these are a no-no if you want to achieve moisture resistance, as moisture penetration is necessary in order to obtain full cure on potting or encapsulation.

Some epoxy resins, too, offer good moisture resistance, as well as a fast cure, hardness and high stability, particularly in variable temperature environments. These also adhere well to most substrates, even difficult substrates with a very low surface tension, such as PTFE, ensuring a water-tight encapsulation.

2) Chemical Protection

So what’s next? You might also need to protect electrical or electronic components that are likely to come into contact with chemicals, including acids, alkalis, solvents and a whole raft of other substances that pose a threat to delicate circuits and components. Chemical resistance is very much the province of epoxy resins, though some of the tougher polyurethane products – as well as some silicone based formulations – will provide a degree of protection. Epoxy resin products are available to protect electrical/electronic units that undergo frequent or permanent immersion in solvents such as diesel fuel, leaded and unleaded petrol and cellulose thinners.

3) Mechanical Shock

Another essential point is the importance of protecting components from mechanical shock and vibration. Here, a more flexible cured product is likely to provide the best solution as it adds a level of compliance which will help insulate the potted components against adverse mechanical movements. In addition to their moisture resistant properties, polyurethane resins also provide this desired level of flexibility and so they are often the first choice for shock and vibration protection. Silicone resins, too, offer excellent flexibility and, in addition, will tolerate high operating temperatures.

One more ‘shock’ that I should mention is thermal shock, which can have a devastating effect on electronic components, shortening their operating lives at best – destroying them completely at worst. The adverse effects of thermal stress can be ameliorated by using two-part epoxy resins, which are best for those applications that undergo severe temperature cycling or which are likely to suffer thermal shock. Some also provide the added bonus of flame retardant technology.

4) Concealment

Finally, it’s worth mentioning that, quite apart from providing all the protections listed above, opaque potting and encapsulation resins also conceal what lies beneath. This could provide an effective foil against counterfeiters or those wishing to copy a circuit layout, helping you to protect your intellectual property.

Summary

When it comes to the choice and applications of resins, there’s a great deal more to discuss, and over the following months I hope to provide some useful tips and design advice that will help you in your quest for reliable circuit protection.