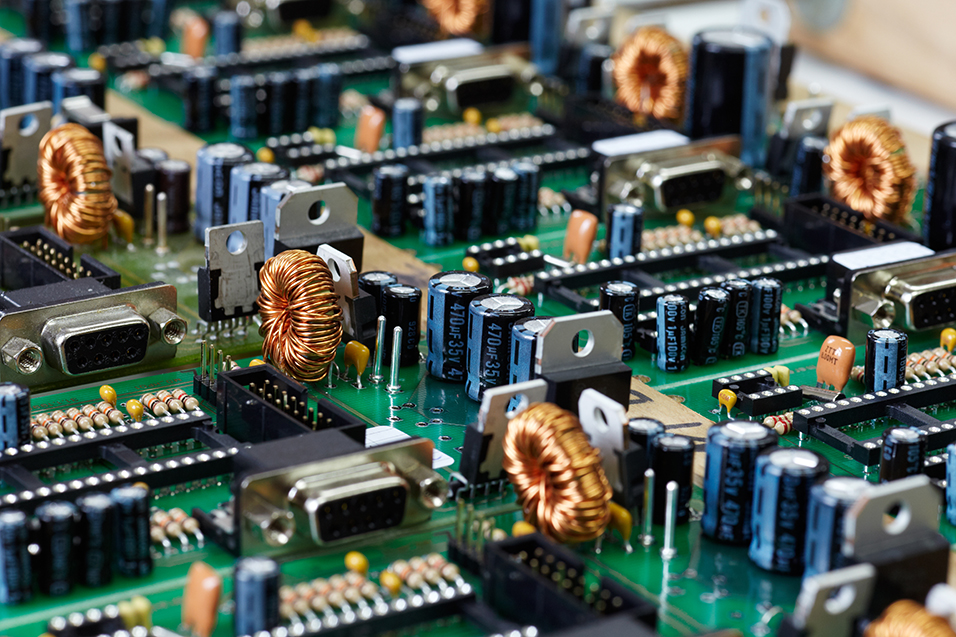

As assemblies become ever more densely populated, and housing /casing designs become more permeable to save weight, the use of conformal coatings is becoming essential to protect the assembly from its operating environment and ensure acceptable reliability for the application intended, especially when operating in hostile environments. In my previous columns, we have covered some of the fundamental considerations of conformal coating selection and performance, examined key benefits of different types of coatings and explored their limitations. For this month’s column, I am going to concentrate on some essential factors regarding the challenges board designs can pose on designers, in order to help you implement a more successful coating operation. So, let’s look at issues that may arise with coating coverage, cycle times and coating flow.

Board Design Challenges

The design of the board can have a huge impact on a successful coating operation, both by determining which methods can actually be used, as well as the degree of coverage that can be achieved within the required cycle time. I’m going to focus on selective coating, being the most common application method, where masking is minimised if not eliminated, but most of the principles will translate to other coating application methods.

In lean manufacturing, the coating cycle time is often the key requirement, ensuring the production takt time can be met, thus maintaining a balanced line. Given that coating is often one of the latter processes in the production line, it is often advantageous for the coating cycle time to be faster than the overall line takt time to ensure any accumulated production can be cleared as rapidly as possible, should any previous operations suffer a stoppage.

In general, the less areas there are on a board that must be free from coating, the faster the coating cycle time will be. Should the coating cycle time be too long, then a decision can be made to either determine the most vulnerable parts of the assembly and focus on that area in the available cycle time, or to split the coating across several workstations.

Coating Cycle Time

Coating cycle time is clearly very important to the balance of the production line, so what kills coating quality and cycle time on a typical selective coating line?

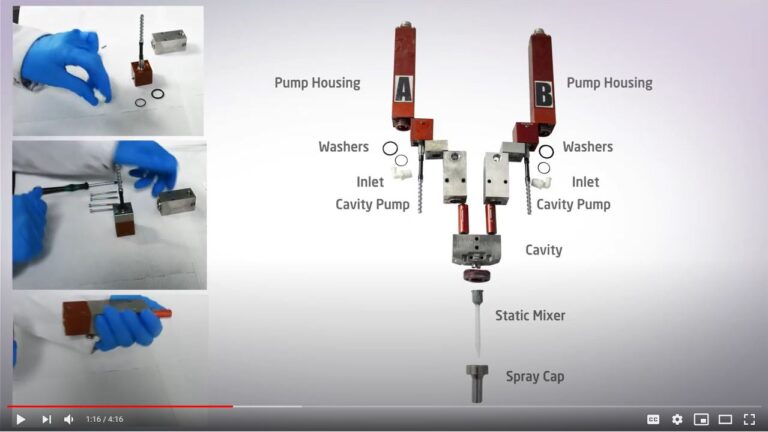

Selective coating machines deposit a stripe of coating material, that can be programmed to stop and start on demand. Stripes of coating can be deposited to create a coating pattern, avoiding areas such as switches, connectors and test points, which must not be coated to prevent interference with form, fit or function. The coating stripes deposited are usually in the 8-15mm range, for optimum accuracy and minimizing overspray and splashing. When the area to be coated is less than 8mm in width, then it is necessary to utilise a dispensing step, which is a cycle time killer.

Due to the combination of machine X/Y positional accuracy, material fluid dynamics and component topography, 2-3mm is usually as close to ‘keep out’ areas as anyone would be comfortable coating for a repeatable process. In summary, ‘must coat’ and ‘keep-out’ areas positioned within 2-3 mm of each other present a problem. Dispensing is also required, representing another process step adding to cycle time.

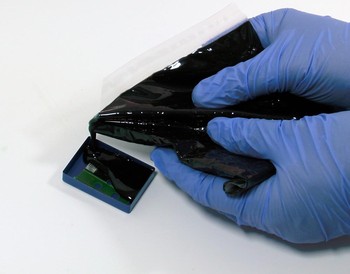

Coating Flow

In manufacturing, for many coatings, it is difficult to limit the flow of coating from the application site to adjacent sites. Most coatings will have some level of capillary flow (often referred to as wicking), taking the coating to unanticipated areas. Therefore, components which MUST be coated should not be placed in proximity to components with MUST NOT be coated.

Coating flow is also an important consideration on low standoff bottom-terminated devices, such as BGAs or QFNs, which may also have microvias under them. Coating can wick under the parts and then down the vias to the opposite side of the assembly. To avoid this problem, the vias under low standoff components can be tented with solder mask or have the vias filled with solder or a suitable via-fill material. Of course, since conformal coating can reduce the solder joint lifetime of bottom terminated devices, deliberately coating beneath these devices should be avoided.

Keep in mind that liquid coatings will flow somewhat during the coating application process, so placing a keep out zone at the base of a tall component, such as an electrolytic capacitor, will create a lot of problems in manufacturing as the coating flows down the tall part into the keep out zone.

Engineering drawings or quality control documents should be very specific on what coating “anomalies” are defects requiring disposition and those which are primarily cosmetic. For many years in the industry, anything that looked different in the coating was considered as a “defect”, requiring ascetically perfect assemblies. While possible, such requirements often drive up the cost of coating and often have no impact on assembly reliability.

Designers should be aware that coating the edges of assembly is not considered as value added for most applications. Most design standards do not allow inner layer circuit traces to be closer than 0.63 mm from the edge of the board. The act of routing the board edges results in smearing the epoxy resin over the cut glass fibers or the reinforcement material, sealing off the inner layers. A designer might specify coating board edges where such sealing does not occur, such as with V-scored, punched, or sheared edges.

Understanding the dynamics of what affects what on the surface of the board during the early-stages of design will go a long way in helping you achieve a successful conformal coating operation. In turn this will also help avoid potential disasters in other areas of production too. If you have any questions, or would like more information about conformal coatings, then there’s a wealth of experience to call upon from our Technical Support Team members who will be more than happy to answer your queries and offer expert guidance.