In my first two blogs in this series, I presented a broad introduction to the subject of thermal management of electronic circuits. I hope my ‘quick start guide’ and ‘problems and solutions’ items have sparked readers’ interest in this elemental but essential aspect of electronic system design.

This month I’m taking a closer look at thermal interface materials – how they can be applied to achieve efficient heat transfer – and the significance of bulk thermal conductivity in relation to heat transfer and thermal resistance. I’ll also be touching on the influence that product miniaturisation is having on thermal management techniques, and I make no excuses for returning once more to answering the recurring question: why do I have to spread my thermal interface material so thinly?

As in previous columns, my approach will be based on the ‘frequently asked questions’ that our customer support teams field every day on the phone, at exhibitions and when visiting customer premises. I’ve selected five of the most common questions, followed by their respective responses, and I hope they offer useful guidance for readers who may be experiencing design problems related to achieving a satisfactory heat transfer performance in their electronic assemblies.

What would be your top suggestions for achieving the most efficient heat transfer?

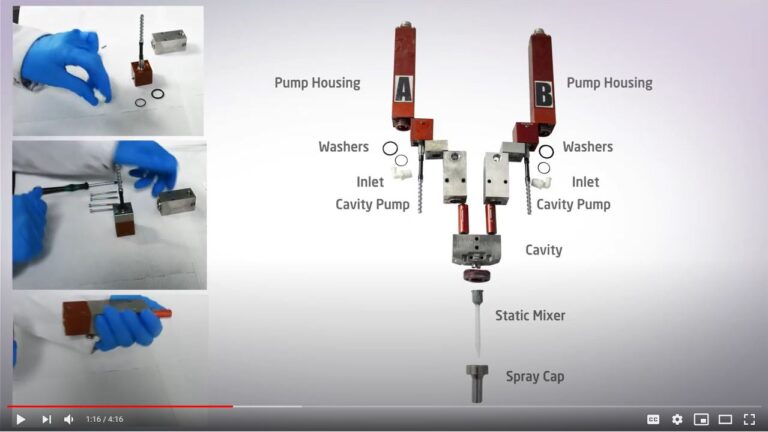

First and foremost, read the thermal interface material manufacturer’s advice about optimum application methods. They’ve been around the block a few times and they know what they’re talking about! Remember, more is not necessarily better; uniform and thin applications of the heat transfer medium always work best. Most products are likely to have an optimum thickness of application, as determined by the manufacturer, and you should try to achieve this for best results.

It is important to understand your application – what are the environmental conditions under which it must operate, and how variable are they? Will the chosen heat transfer compound perform consistently as environmental conditions swing from one extreme to the other? Consider the heat sink – is this the actual casing surrounding the assembly or a separate heat sink placed on top of a component? Where cases are concerned, is there a gap between the case and the component?

What key issues must be considered when trying to achieve efficient heat transfer?

Again, think variability of environmental conditions. Just because the heat transfer is efficient under standard ambient conditions, doesn’t mean that it will remain stable over the lifetime of the product. Accelerated testing might be able to reveal related design issues; however, in-application testing is more likely to provide definitive information about the long term performance of heat transfer materials.

Application of the heat transfer compound will depend on the type of interface or gap filling material being used. These compounds provide a medium for improving the conditions under which heat transfer takes place and thereby maximise its efficiency. Compounds should not be applied in excess amounts in the belief that they will achieve the thermal conductivity of a solid metal heat sink.

Remember, high thermal conductivity doesn’t necessarily mean high heat transfer. This will depend on the thermal resistance achievable with a particular thermal compound and how effectively it can be applied in an optimally thin film.

What tips can you give about measuring bulk thermal conductivity and making effective comparisons between different thermal management products?

Bulk thermal conductivity can be measured in lots of different ways. Nowadays, the equipment available for measuring this parameter is very accurate, but the methods of measurement are likely to differ from one laboratory to another. If a true comparison of bulk thermal conductivity is required, it is advised that the same equipment and conditions are used for comparison purposes.

Bulk thermal conductivity is only the transfer of heat through the thermal management material itself. The measurement is usually taken using much greater thicknesses of the material than would be used in a real application and it will not be representative of the thermal resistance that would be expected for that application. My company always advises that thermal management products are applied in a real-world application so that the efficiency of heat transfer can be tested under the specific conditions of use.

How has the trend for product miniaturisation affected the thermal management materials market?

Product miniaturisation is increasing the need for efficient thermal management within devices. As devices get smaller, the spacing between components also gets smaller and any heat generated by these components is concentrated at specific areas of the PCB. Components that generate a lot of heat could therefore adversely affect other nearby components which, due to miniaturisation, are much closer to one another. Excessive heat can ‘age’ PCBs and components, consequently shortening their lifespan. By using effective thermal management techniques, excessive heat can be dissipated, enabling densely populated designs to be realised without compromising the life expectancy of the device.

Why do the majority of thermal interface materials have to be applied in very thin layers?

A heat sink is usually made from a solid piece of metal that has a much higher bulk thermal conductivity than a thermal interface material. At a microscopic level, the interface between the component and the heat sink is likely to be uneven and air will be trapped within this space. Air is a very poor conductor of heat so an intervening thermal interface material layer is applied to remove these air pockets and therefore improve the interface’s thermal conductivity.

The thermal interface material reaches optimum thickness when all the air is expelled and a uniform film is achieved, maximising the contact area of the component to the heat sink. Anything in excess of this is relying upon the thermal conductivity of the thermal interface material itself and as we know, this is nowhere near as thermally conductive as solid metal. So, the golden rule is: apply only as much as is required to remove air and improve the quality of the mating surfaces; that way you will achieve the most efficient heat transfer between a component and its heat sink.

Electrolube has a large portfolio of thermal management products and has invested extensively in product research and development. As always, I strongly recommend you take advantage of this and get some expert advice before you settle on any particular material or processing method.