In my last blog, I gave a summary of essential factors to consider when embarking on conformal coating selection and looked at those all-important considerations to get the best performance for your application. For this month, I’m going to cover five commonly asked questions about conformal coatings that every Design Engineer should be mindful of when specifying the coating process. Identifying potential production problems at the design stage will always be favourable and far easier than trying to fix problems or concerns following conclusion of the engineering drawings. So, let’s return to our trusted Q&A format and explore these five key points in more detail, which I hope will go some way in helping you achieve the best outcomes for your coating processes and help you make new production friends in the meantime!

1) How important is the reworkability characteristic of a coating?

Believe it or not, reworkability of a coating can often be a very important consideration in the selection of a conformal coating, especially when boards are of high value, and have long service life expectancies, e.g. Military and Aerospace assemblies. A coating may display many favourable characteristics that make it superior for assembly protection in the field, but it might also make the assembly very difficult to rework in the factory or repair in the field. A difficult-to-rework coating will not only make repairs and upgrades time consuming, but will also add cost and complexity to the product.

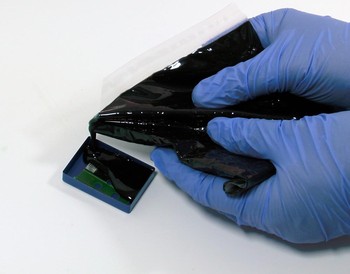

If the assembly is likely to require repair, modifications or upgrades, then consideration should be given to the ease of removal of the coating. During the rework or repair process, it is likely that components will be replaced so it is highly advantageous that the coating can be easily and cleanly removed from the required areas to facilitate these repairs, and that the coating has good adhesion to itself to ensure that an effective and permanent seal can be made to the repaired area. Complex issues can be avoided entirely if the reworkability factor is taken into account during the coating selection process. Manufacturers like us do offer products for the effective removal of conformal coatings, including those that are solvent resistant, but frankly with the right conformal coating product for your application, it can be easy to completely remove the entire conformal coating prior to repair. So, do keep reworkability in mind when selecting your coating product, as you can save yourself a lot of aggravation in the long term.

2) Does a thicker level of coating coverage equal greater protection?

This is a good question that we get asked a lot and the simple answer is ‘it depends’. Thicker coating coverage can achieve greater protection of your assembly from an end use environment. However, it is not unusual for end users to push the limits on coating thickness, favouring thicker films of coating for a number of reasons, such as protecting the assembly from a harsh environment or simply for additional peace of mind. That being said, conformal coatings should not be applied in thicknesses greater than necessary, or exceed the thickness they were designed to be applied at.

In fact, very thick application of conformal coatings can actually result in harmful levels of stress on components, vastly extend the manufacturing/curing times, and depending on the cure method, cause inadequate adhesion to the substrate. Designers should not specify coating fillets around Bottom Terminated Components (BTCs) such as BGAs or QFNs, as capillary forces will pull conventional coatings under the part, which may result in reduced solder joint lifetime, especially during thermal transitions. Conformal coatings are normally applied to circuit boards by dipping or spraying, typically at a thickness of 20-50 micron, although conventional silicone and other specialist coatings can be applied at up to 200 micron thickness. However, we have created an interesting option here for the industry by developing the 2K coatings range, which can be applied at much greater thicknesses from 100-300μm than the average coating. But there is a reason for this. 2K conformal coatings are solvent-free and have been formulated to perform at these greater thicknesses, with the same ease of application as a conventional conformal coating and are particularly suitable for protection against particularly harsh, condensing environments. So there certainly won’t be any need for angst over coating thickness with these particular coatings!

However, the moral of the story is quite simply this…in order to obtain the maximum levels of protection available from the coating, it is pretty much imperative that the coating is applied in the ranges of thickness specified on the datasheet. If you are in any doubt about appropriate coating thickness, always consult the datasheet or get the advice of a reputable supplier: they have laboured hard to establish optimum coating thicknesses for their products in all kinds of operating environments. You really don’t need to apply coatings any thicker than specified for additional protection or it could result in diminishing returns later on, instead, work on achieving the very best degree of coverage for a given thickness range – coverage is often more important than thickness, except in the harshest environments.

3) How can designers ensure a smoother production process – for example, how do they indicate whether it really doesn’t matter if a component is coated or not?

When design and production work seamlessly well together, the outcome will nearly always be successful, particularly when a designer understands the intricacies of conformal coatings. One area where designers can really help their production colleagues is to specify where coatings are optional or “don’t care” in the engineering drawing. An example of this, for instance, is LEDs on a circuit board. When the spectral output of the LED is important to the product function, and coating the LED would interfere with that function, then the LED should not be coated. If the LED is on the assembly as a test select, and the presence of conformal coating, assuming transparency, does not interfere with the assembly function, then it may be coated. In specifying the optional coating, the designer provides more flexibility to the coater in assembly operations. It is best practice to specify the areas that need to be coated and the areas that don’t as well as the ‘don’t care’ areas to help the coating process run as smoothly as possible.

4) Can a designer’s instructions be easily misconstrued?

We might need to duck for cover here, but the answer is yes! Engineering drawings should avoid specifying “100% coverage” as this means many different things to many different people. The only real way to get 100% coating is to have assemblies with no connectors, no uncoated components, and be either dip coated or vapor deposited. In practice, you can only inspect coatings in areas that are visible to the inspectors. Inaccessible areas cannot be inspected.

5) How is coating thickness specified?

Cured conformal coating thickness varies by chemistry. It’s also advisable to be aware of what these coverage requirements do to your resulting application method. Adequate coverage particularly on corners, sides or under leads can be a challenge in thin film applications, whereas thick film processes can increase the flow characteristics of a coating application and can be more difficult to manage around no-coat areas. When specifying the thickness of coating on an engineering drawing, the industry practice is to measure coating on a flat, unencumbered area of the assembly, and not on items like component leads. As many modern assemblies are very component-dense, it is often difficult to find a flat, unencumbered area of the assembly. Consequently, it is a common and accepted practice to use witness or process control coupons for such measurement.

Designers will need to know that the ‘nominal thickness’ measured on flat, unencumbered areas or witness coupons will have no relation to the thickness of coating achieved on the corner of a discrete, or the leads of ICs, where thickness might be in the order of 1 micron or less, with a nominal thickness of 25 or 50 microns. In a recent study, performed by the IPC, ‘Conformal Coating – State of the Industry’ there were some very eye-opening results for many folks who assumed they were getting 25 microns everywhere. Again, the key take away is nominal coating thickness is a process indicator only, the actual coverage on leads and components is far more important to the reliability of the assembly and this should be understood by all parties. The goal is the greatest degree of coverage possible, and that cross-sections should be performed to understand how the application process is delivering this critical to success parameter. The witness coupon will only tell you if your process has changed significantly.

6) How is the best method of application determined?

There isn’t necessarily a best method to apply a conformal coating. Choosing the most pertinent application method for a particular assembly will depend upon which existing equipment is available to the manufacturer, the coating processes in use, the average time interval between the start of production of one unit and the start of the next and the overall design of the assembly, which will dictate what can and cant be achieved. This includes those areas of the circuit which must be coated and those which must not (connectors, switches, test points, RF shielding and so on). The ‘best’ application method would ensure that each board to be coated receives coating coverage on all required metal surfaces at a sufficient thickness to afford protection against the environment. These requirements will change from board design to board design, and environment to environment and invariably they need to be tested and verified ahead of the production run.

Implementing a defect-free conformal coating process is a fine balance of material selection, understanding the engineering requirements for coverage (coat, no-coat and don’t care areas), and thickness, as well as choosing a suitable application method. Understanding the subtleties of conformal coatings will pay huge dividends in providing an engineering drawing that isn’t prone to misinterpretation and making the production team’s lives easier. When it comes to designing for conformal coating, there’s a great deal more to discuss and over the following months I hope to provide more useful tips and design advice that will help you accomplish reliable circuit protection. At Electrolube, we talk solutions every day, so if you have any questions about conformal coating selection, performance, thickness, coverage and so forth, please do talk to us.