Specifically designed and formulated chemical products are widely used in the electronics industry for a vast array of applications. Whether it is during PCB manufacture or for the protection of components or complete devices, such products have become an essential factor in ensuring the performance and quality of electronic devices.

The subject of this paper is to discuss the application of these formulated chemical products for thermal management applications, specifically within the rapidly expanding LED industry. As we are all aware, LEDs have been present in many electronic devices for a number of years. More recent developments in this industry have lead to their vast array of use in all types of lighting, signage and domestic appliance products, to name but a few. In offering alternatives to halogen, incandescent and fluorescent lighting systems for both interior and exterior applications, the possibilities for LEDs are seemingly endless. LEDs offer advantages over traditional lighting forms in terms of adaptability – allowing more design freedom due to the reduced space required and exceptionally long life time, resulting in a cost effective solution for many applications. They are also considerably more efficient, converting the majority of energy to light and thus minimising the heat given off.

Although LEDs are considerably more efficient than traditional lighting forms, they do still produce some heat. This heat can have an adverse effect on the LED and therefore must be managed to ensure the true benefits of this technology are realised. Typically categorised by colour temperature, LEDs are available in a huge number of colour variants. With a change in operating temperature of the LED, a change will also occur to the colour temperature; for example, with white light an increase in temperature could lead to a ‘warmer’ colour being emitted from the LED. In addition, if a variance in die temperatures is present across LEDs in the same array, a range of colour temperatures may be emitted, thus affecting the quality and cosmetic appearance of the device.

Maintaining the correct die temperature of the LED can not only extend the life but also lead to more light being produced and therefore, fewer LEDs may be required to achieve the desired effect. Therefore, an increase in operating temperature can have a recoverable effect on the properties of the LED, however if excessive junction temperatures are reached, particularly above the maximum operating temperature of the LED (~120-150˚C), a non-recoverable effect could occur, leading to complete failure. Operating temperature is a directly related to the lifetime of the LED; the higher the temperature, the shorter the LED life. Ensuring efficient thermal management is employed will therefore provide consistent quality, appearance and lifetime of LED arrays and in turn, opens up the opportunity for further applications for this ever evolving industry.

The principles of thermal transfer can be discussed in detail however, for the purpose of this paper, we shall briefly address the basics; conduction (heat transferred through a solid mass via direct contact – Fourier’s Law), convection (transfer of heat through the movement of fluids and gases – Newton’s Law) and radiation (the heat transferred through an electromagnetic field). Radiation typically only has a very small effect on the heat transfer of LED systems since the surface areas are relatively small and so it is the principles of conduction and convection that we are most interested in here: Conduction refers to the transfer of heat at the LED junction, between the LED and the heat sink, whereas convection refers to the transfer of heat from the heat sink to the surrounding air.

Newton’s law of cooling states that the rate of loss of heat is proportional to the temperature difference between the body and its surroundings. Therefore, as the temperature of a component increases and reaches its equilibrium temperature, the rate of heat loss per second will equate to the heat produced per second within the component. Since heat is lost from a component to its surroundings at its surface, the rate of dissipation will increase with surface area. This is where heat sinks are used – varying in size and shape, heat sinks can be designed to offer a significantly increased surface area to maximise heat dissipation. Heat sinks are often used in LED applications and fix onto the back of the component. Ideally, these mating surfaces should be perfectly smooth enhancing the efficiency of heat conduction, but this is not usually possible. As a result, air gaps will be present at the interface of the device and the heat-sink, significantly reducing the efficiency of heat transfer.

There are many ways to improve upon the thermal management of LED products and therefore, the correct type of thermally conductive material must be chosen in order to ensure the desired results for heat dissipation are achieved. Thermal interface materials, such as a heat transfer compounds work to remove any air gaps present between mating surfaces and improve the efficiency of heat conduction at the LED junction. Such compounds are designed to fill the gap between the device and the heat sink and thus reduce the thermal resistance at the boundary between the two. This leads to faster heat loss and a lower operating temperature for the device. Curing products can also be used as bonding materials; examples include silicone RTVs or epoxy compounds – the choice will often depend on the bond strength or operating temperature range required. Solid materials such as gap filling pads and phase changing materials are also a possibility, where a thin film substrate is used at the interface. During the process of product selection, it is always important to question whether a curing product is required to help bond the heat sink in place, or whether a non-curing thermal interface material is more appropriate to allow for rework.

Silicone and silicone-free non-curing thermal paste products are also available; the silicone products offer a higher upper temperature limit of 200˚C and a lower viscosity system, due to the silicone base oil used. This leads us to our next detail in product selection as the use of products based on, or containing, silicone may not be authorised in certain applications. This could be due to a number of factors, including application requirements or where problems exhibited in cleaning or adhesive processes are observed. Such issues are due to the migration of low molecular weight siloxanes; these volatile species can lower the surface tension of a substrate, making them extremely difficult to clean or adhere to. In addition, due to their insulative nature, migration of low molecular weight siloxanes can lead to failures in electronic applications. Here at Electrolube, we formulate products from raw materials specifically designed for the electronics industry. Thus, silicone containing products are only utilised where the low molecular weight fractions are monitored and kept to an absolute minimum. As an alternative, a range of non-silicone products are also provided for critical applications.

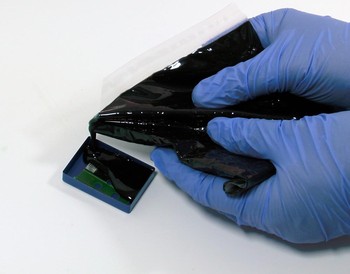

Another option for managing the transfer of heat away from electronic devices is to utilise a thermally conductive encapsulation resin. These products are designed to offer protection of the unit from environmental attack whilst also allowing heat generated within the device to be dissipated to its surroundings. In this case, the encapsulation resin becomes the heat sink and conducts thermal energy away from the device. Such products can be used to encapsulate the technology behind and attached to the LED device and can also assist with the reflection of light back from within the unit, depending on the colour chosen. Encapsulation resins also incorporate the use of thermally conductive fillers however the base resin, hardener and other additives used can be altered to provide a wide range of options, including epoxy, polyurethane and silicone chemistries.

The different chemistry options will provide a range of properties and each should be considered depending on the end application requirements. For example, a polyurethane material offers excellent flexibility, particularly at low temperatures, a major advantage over an epoxy system. A silicone resin can also match this flexibility at low temperatures as well as offering superior high temperature performance, well in excess of the other chemistries available. The silicone products are also typically more expensive. Epoxy systems are very tough and offer excellent protection in a variety of harsh environments. They are rigid materials with low coefficients of thermal expansion and in some cases, a degree of flexibility can be formulated into the product. The formulation of encapsulation resins can lead to a vast array of products with tailored properties for individual applications and therefore it is advised that applications are discussed in detail with a relevant material supplier.

Regardless of the type of thermal management product chosen, there are a number of key properties that must also be considered. These can be quite simple parameters, such as the operating temperatures of the device, the electrical requirements or any processing constraints – viscosity, cure time, etc. Other parameters are more critical to the device and a value alone may not be sufficient to specify the correct product.

Thermal conductivity is a primary example of this. Measured in W/m K, thermal conductivity represents a materials’ ability to conduct heat. Bulk thermal conductivity values, found on most product datasheets, give a good indication of the level of heat transfer expected, allowing for comparison between different materials. Relying on bulk thermal conductivity values alone will not necessarily result in the most efficient heat transfer, however.

Thermal resistance, measured in K m2/W, is the reciprocal of thermal conductivity. It takes into account the interfacial thickness and although it is dependent on the contact surfaces and pressures applied, some general rules can be followed to ensure thermal resistance values are kept to a minimum and thus maximising the efficiency of heat transfer. For example, a metal heat sink will have a significantly higher thermal conductivity than a heat transfer compound used at the interface and therefore it is important that only a thin layer of this compound is used; increasing thickness will only increase the thermal resistance in this case. Therefore, lower interfacial thicknesses and higher thermal conductivities give the greatest improvement in heat transfer. In some cases, however, utilising a material with a higher bulk thermal conductivity could be to the detriment of contact resistance and thus, no improvement will be accomplished. The table below provides some indications of the differences between thermal management materials and how the combination of properties is more important than a single value alone.

An example of this difference can be drawn from the comparison of thermal compounds or pastes and thermal pads, as shown in table 1. Thermal pads are solid, polymerised materials of a fixed thickness which are available in a variety of thermal conductivities. Thermal compounds or pastes, as discussed above, are non-curing compounds and as a result, their viscosity can alter slightly as the temperature increases. This allows for a further reduction in interfacial resistance. In the case of thermal pads, high pressures are needed to achieve an adequate interface, thus, a paste and pad of similar bulk thermal conductivity may have very different thermal resistance measurements in use, and as such a difference in the efficiency of heat transfer will be observed.

Another concern with using bulk thermal conductivity values alone for product selection is that there are a number of different techniques available. Significant variations in thermal conductivity values for the same product can be achieved by utilising different test methods or parameters. This can result in bulk thermal conductivity values that appear very high when quoted but in use have a dramatically reduced efficiency of heat dissipation. Some techniques only measure the sum of the materials’ thermal resistance and the material/instrument contact resistance. Electrolube use a version of the heat-flow method that measures both of these values separately, giving a much more accurate bulk thermal conductivity measurement. Whichever is used, it is essential that products are compared using the same method to obtain bulk conductivity values and in all cases, the products should be tested in the final application for a true reflection of effective heat dissipation.

This leads us to another important factor in product selection, the application of thermal management materials. Whether it is an encapsulation compound or an interface material, any gaps in the thermally conductive medium will result in a reduction in the rate of heat dissipation. For interface materials, the viscosity of a product or the minimum thickness possible for application will have a great effect on the thermal resistance and thus, a highly thermally conductive, high viscosity compound that cannot be evenly spread onto the surface, may have a higher thermal resistance and lower efficiency of heat dissipation when compared to a lower viscosity product with a lower bulk thermal conductivity value. For encapsulation resins, this could be expressed in a similar way; the higher the viscosity, the more difficult it is for the resin to flow evenly around the unit and therefore, air gaps are formed in the potting compound reducing the rate of heat dissipation. It is essential that users address bulk thermal conductivity values, contact resistance, application thicknesses and processes in order to successfully achieve the optimum in heat transfer efficiency.

A practical example highlighting the requirement for such considerations is provided in Table 2 and the subsequent graph below. It shows the potential differences in heat dissipation by measuring the temperature of a heat generating device in use. These results have been based on work completed by an end user, where all products were thermal interface materials, applied using the same method, at the same thickness.

It is clearly evident that a higher bulk thermal conductivity value, in this case 12.5 W/m K, does not necessarily result in more effective heat dissipation when compared to products with lower values, such as the above at 1.4 W/m K. The reason for this could be due to the processing method not being suitable for the product, for the product not being easy to apply or possibly the product was not designed for this particular application. Whatever the reason, it highlights the importance of product application as well as product selection.

With such rapid advances in the electronics industry and more specifically, LED applications, it is imperative that materials technology is also addressed to meet the ever demanding requirements for heat dissipation. Electrolube have developed specific technologies to improve the ability to process thermal management compounds, easily and effectively. This has resulted in reduced viscosity compounds with higher bulk thermal conductivities and with these two properties combined these products provide maximum efficiency in heat dissipation by minimising thermal resistance. This technology has now also been transferred to encapsulation compounds, providing products with higher filler loadings and thus improved thermal conductivity combined with improved flow. In addition, Electrolube also manufacture a range of products other than thermal management materials. Such products include conformal coatings and encapsulation resins in optically clear formats for applications where protection of the entire LED is required, once again reaffirming the importance of continually developing formulated chemical products to meet the rapid and demanding requirements of this popular technology.

Jade Bridges

European Technical Support Specialist