Welcome to my second blog in the Encapsulation Resins series. If you missed last month’s blog, I’m Beth Massey, Global Product Manager for Encapsulation Resins. This month, I have collaborated with fellow resin expert Beth Turner, Senior Technical Specialist, to give you the clearest focus of how introducing bio-based resins systems will impact on your production process and the benefits they bring in terms of performance. We have recently experienced the confusion that can ensue when a department has two people with identical names working on resins. Hopefully, this blog should help to demonstrate the different input from Beth Massey (PM) and Beth Turner and dispel any confusion.

Many of you will have already seen Electrolube’s news about a new range of bio-based resins, and in this blog we are going to dive deeper into how bio-based resins differ from their traditional counterparts and examine what they can bring to the table, aside from their obvious sustainable and environmentally-friendly benefits.

What percentage of the overall content can reasonably be bio-based without causing a detrimental effect to the performance of the product and is the bio content added to part A or B?

Beth Turner; The honest answer to this question is quite simply it depends. Realistically up to 70% of content can be bio-based, and both A and B can contain bio-based materials. The 70% limit is more to do with availability of bio-based alternatives than due to high levels having a detrimental effect. It’s likely that some components of the formulation will never have a bio-based alternative, but the benefits we are seeing from changing to bio-based raw materials where possible does suggest we should push to include as high a content as possible. It goes without saying that bio-coatings have significantly less impact on the environment and meet the ethical needs of manufacturers and end users. However, the most surprising benefit observed has been the improvement in terms of performance. Even additives such as powders can be bio-based.

Does a particular chemistry, i.e. epoxy or PU lend itself to removing some of the chemicals present and substituting them for bio-based content. If yes, why is this?

Beth Turner; Both are suited. If we refer to Beth Turner’s award winning whitepaper on next generation bio-resins, Beth states, “Nature offers an abundance of macromolecules and smaller molecular weight compounds that provide renewable sources for polymers, as opposed to crude oil. These renewable resources make ideal structural backbones for the synthesis of biopolymers, renewable-based monomers, fillers and additives, the key ingredients for polyurethane and epoxy thermoset materials. Research and development to promote innovative solutions that lead to a sustainable economy shows that bio-based materials can deliver a viable alternative to materials derived from crude oil, even in electronic encapsulation applications.”

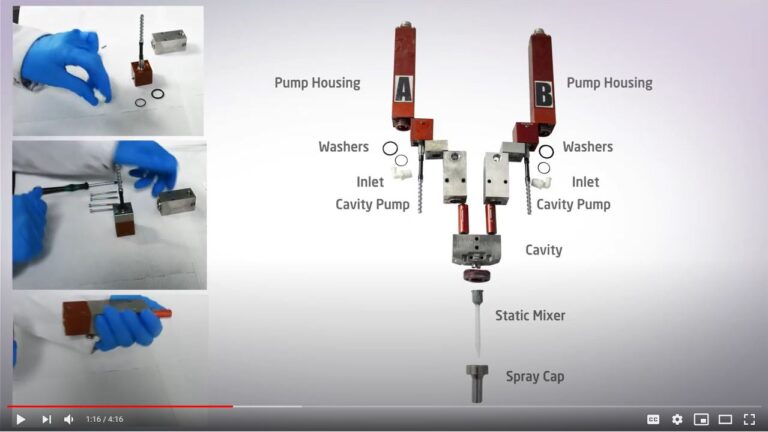

Do bio-based resins behave in a different way when being poured or when curing compared to their chemical versions, and are the tech data sheets almost identical in terms of the qualities exhibited?

Beth Turner; Interestingly, bio-based resins show the same dispensing behaviour and cure profiles as conventional resins, so there is no need to invest in adaptive equipment. There is no negative effect on processability or curing from using bio-based materials and performance is equivalent. However, we do see significant benefits in cured properties when select bio-based raw materials are used. Combining a bio-based polymer matrix and hardener with a biogenic filler offers a significant improvement in thermal conductivity compared to a fully synthetic polyurethane using a synthetic polymer matrix derived from crude oil and mineral rock filler. The bio-based resin also offers better electrical insulation and thermal stability while also having a higher resistance to hydrolysis vs a synthetic polyurethane resin.

Are bio-based products gaining popularity purely due to their association with sustainability or do they exhibit qualities that are superior to their chemical alternatives?

Beth Massey; Initial interest is often sparked because of the increasing focus on sustainability but this is then extended by research that has shown significant performance benefits for bio-based resins. The best way to succeed with bio-based products is to ensure consumers do not have to compromise on quality in order to make the more sustainable choice. As was documented in Beth Turner’s whitepaper, use of certain bio-based raw materials offers substantial benefits in terms of the cured resin’s electrical and thermal performance vs synthetic based raw materials. The fact that these high performance bio-based materials are a more sustainable solution is really an added bonus. It’s especially exciting that some of the raw materials tested were from biogenic waste, adding another layer of sustainability by repurposing waste material from other industries.

In your experience, is sustainability something that genuinely affects manufacturers and their reputation in the market as doing their absolute best to reduce their carbon footprint, or is this more of a box-ticking exercise?

Beth Massey; I think we are seeing a sea of change in attitude at the moment, from sustainability having been seen as a niche focus area to now being a big concern for society as a whole. In the past, the focus has almost been on sustainability as a marketing tool, leading to “greenwashing”, but more and more manufacturers are realising that sustainability needs to be at the core of what they do, both to meet increasing consumer demands for sustainable products and in order to future-proof their business. We’ve seen supply shortages and price volatility making synthetic materials, such as those derived from crude oil, a much less attractive choice, which adds an additional commercial incentive towards using more sustainable bio-based materials. The fact that our research shows using certain bio-based materials in the formulation improves resin properties also means a bio-based resin doesn’t need to be sold on sustainability credentials alone, its performance speaks for itself, as can be seen with our UR5645 high temperature, chemically resistant polyurethane resin.

Electrolube’s extensive research and findings conclude that the future looks extremely promising for bio-based resins, which bring distinct performance advantages in harsh environments, including underwater applications as well as hot and humid operating environments. Bio-based chemicals are highly suited to a wide variety of applications within the electronics industry and even lend themselves to RF applications. Electrolube’s UR5645 has a bio-sourced content of over 60% and has been used in many sensor applications. It is likely that the bio-based chemical share within the electrochemical production segment will increase, and electrochemical manufacturers and associated OEMs will become an important part of the bio-economy of the future. Please do contact one of our Technical Support team to learn more about how bio-based resins can be implemented into your application.